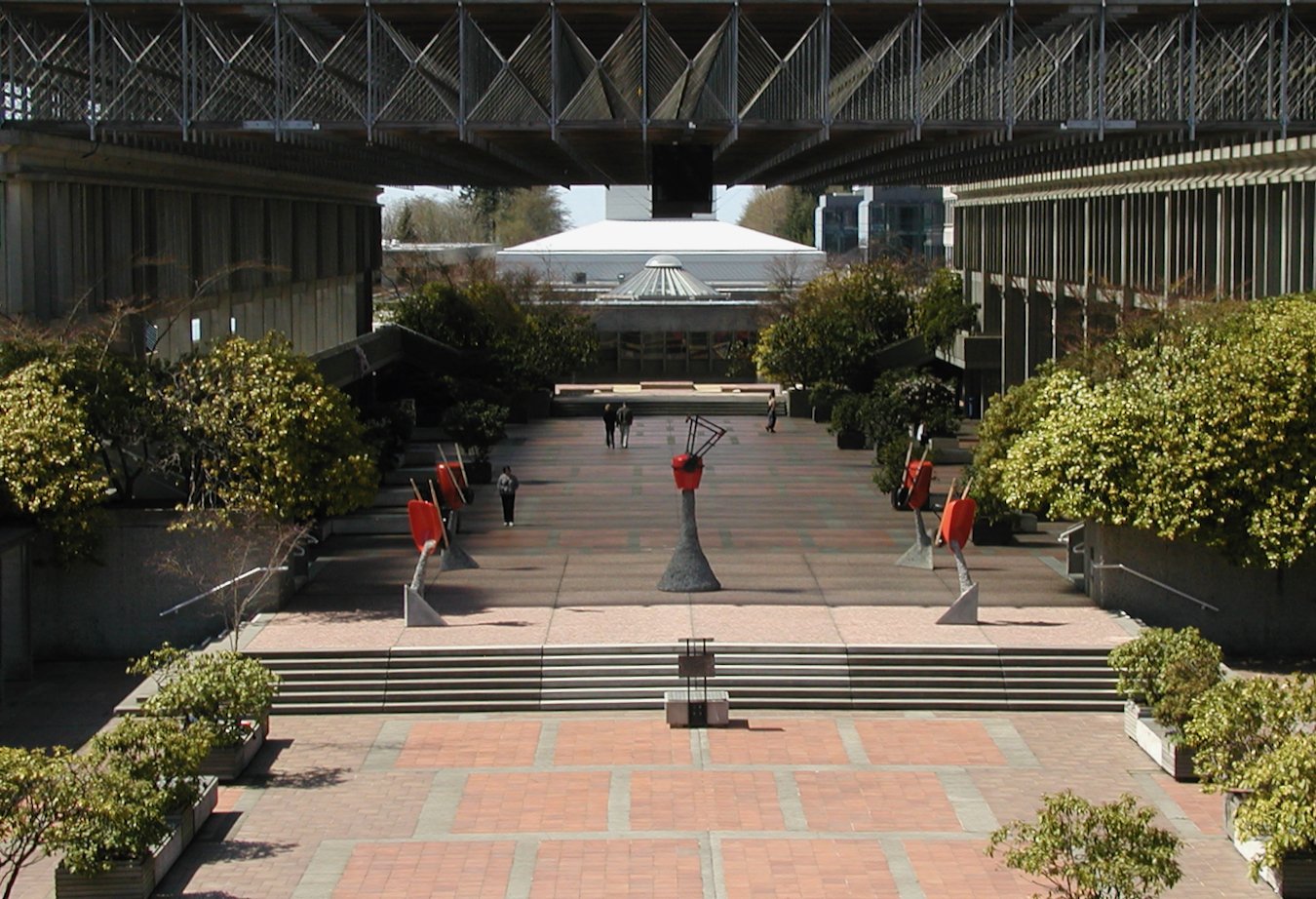

Concrete Progress

concrete, steel, wood, rubber, electric motor

12’ x 50’ x 50’

2002

This piece, representing concrete’s endless production, has a motorized set of wheels slowly rotating above the mixing drum. Four outlying wheelbarrows pour the foundation corners for some newly projected structure. Concrete Progress, as a small-scale cornucopia of concrete with its twisting mixer deliriously turning over its solidified pour, acts as a cipher for the world’s unregulated and universalized production of concrete, replicating the global construction industry's continued and unrelenting expansion in the face of disasterous planetary heating and untrammeled carbon production.

Every tonne of concrete is 10-15% cement, concrete’s basic ingredient. Cement is made from calcinated limestone, through a process producing nearly a tonne of carbon dioxide for every tonne of cement. Twice as much concrete is used worldwide as the total of all other building materials combined. Annual world consumption of concrete now exceeds 3 billion tonnes (3 gigatons), producing 1.6 billion metric tonnes of CO2 Outside of China, the largest cement companies are the German Heidelberg Group (80 million tonnes; owners of Ocean Cement), and the French Group LaFarge (sold 100 million tonnes worldwide in 2007). China produced 1.3 billion tonnes of concrete in 2007, and consumed half the world’s total. The Three Gorges Dam on the Yangtse River, the world’s largest hydroelectric project, has consumed 60 million tonnes of concrete (35.6 million cubic yards, or 27.2 million cubic meters).

Every year, quarries on Texada Island, north of Vancouver in the Salish Sea, ship 6 million tonnes of limestone for processing into cement to two plants across from each other on the Fraser River. On the north bank, Heidelberg produces 1.27 million tonnes of cement a year; on the south bank, LaFarge produces 1.2 million tonnes a year. These plants supply markets throughout the Pacific northwest, including Vancouver and Seattle.